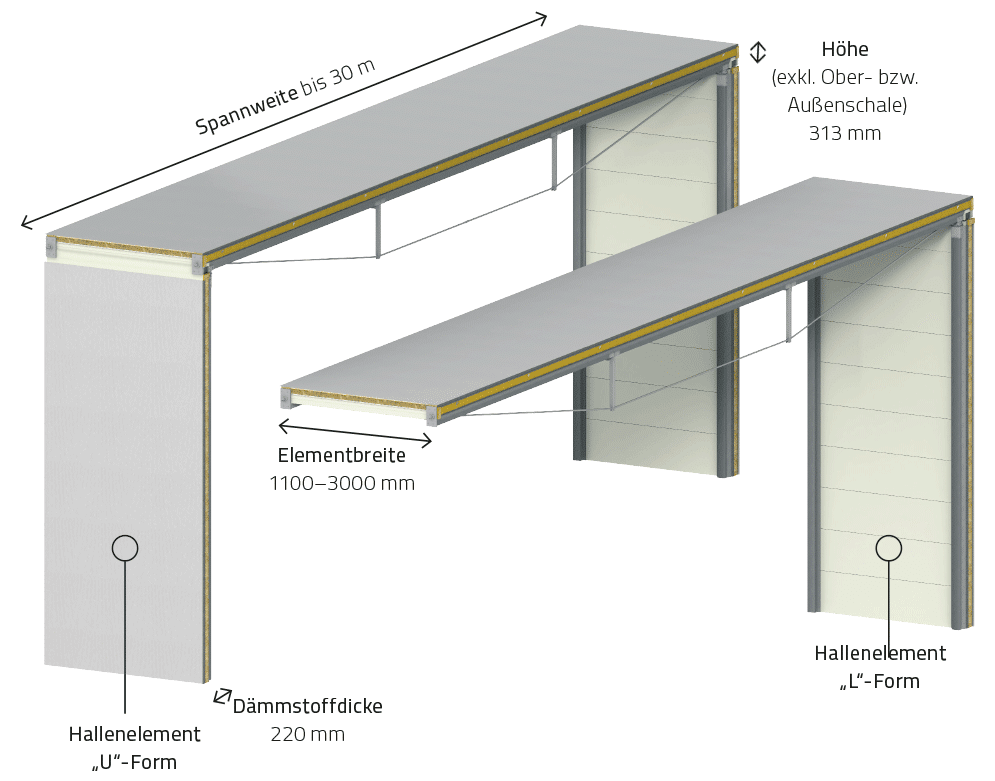

- Thanks to the special underclamping technology

are Hall widths

free bridgeable up to 30 m –

with intermediate supports the

hall width can be multiplied.

- Excellent structural physics

Properties

- top and outer shell as standard

with Domitec and Planum profiles

- Extendable at any time

- Openings in the hall will be

factory taken into account

- Element hall with one floor area

from 750m² in 10 working days

from strip foundation ready

are Hall widths

free bridgeable up to 30 m –

with intermediate supports the

hall width can be multiplied.

Properties

with Domitec and Planum profiles

factory taken into account

from 750m² in 10 working days

from strip foundation ready

The courage to rethink things.

This is how innovation becomes motivation.

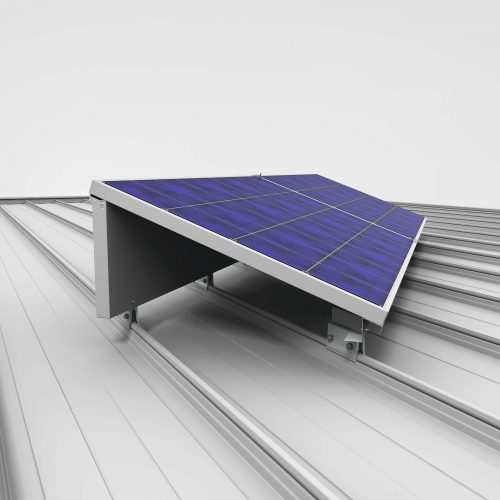

Reduced construction time, economic efficiency and safety – these were the requirements with which the DOMICO Element Hall was developed with flexible usability. Each hall is manufactured to exact dimensions according to the order. With the exact production of the hall elements, the simple and quick erection on site is thus predetermined. A strip foundation or a floor slab is sufficient for the substructure of the hall. The element hall can be extended at any time, since, for example, the gable wall can be easily dismantled and re-assembled. Even extensions to existing buildings are easy to realise with this construction method.

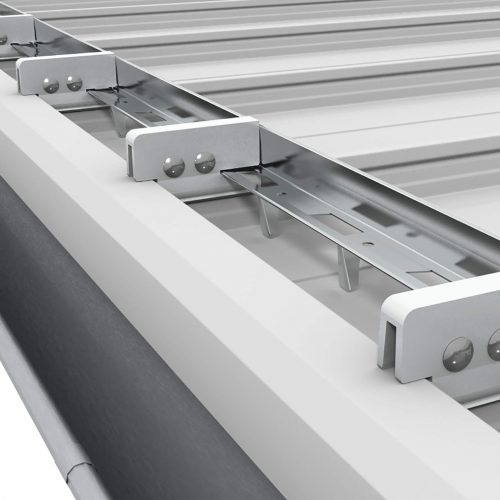

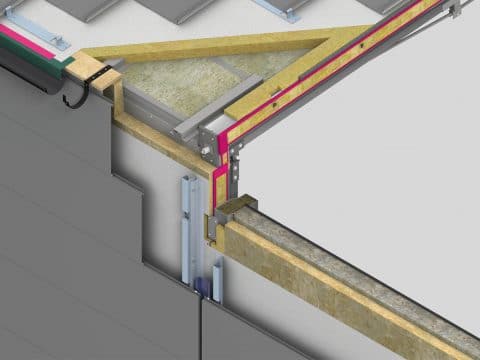

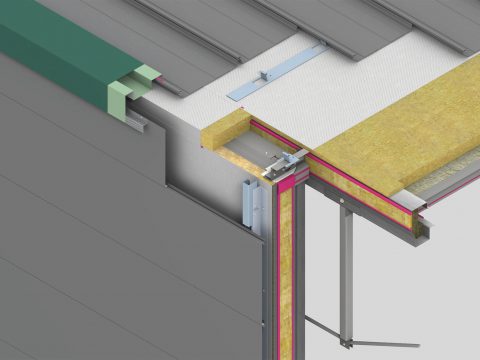

Eaves construction - transition element-roof -

Element wall with Planum outer shell horizontal

Eaves construction - transition element-roof -

Element wall with Planum outer shell horizontal

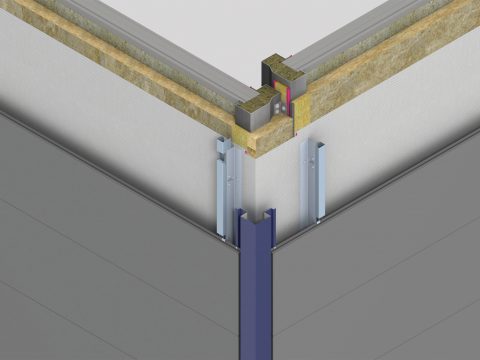

Hall corner construction - Planum outer shell

horizontal with shadow gap outside corner

Hall corner construction - Planum outer shell

horizontal with shadow gap outside corner

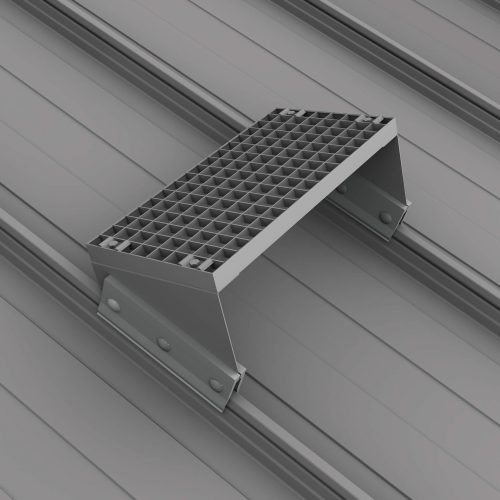

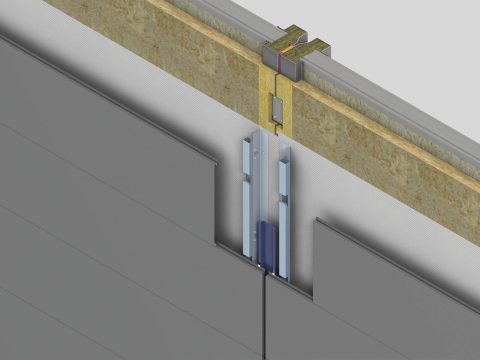

Element wall - element joint with shadow gap, shear field formation and horizontal planum outer shell

Element wall - element joint with shadow gap, shear field formation and horizontal planum outer shell

verge construction - transition element-roof -

Element Gable wall with Planum outer shell horizontal

verge construction - transition element-roof -

Element Gable wall with Planum outer shell horizontal